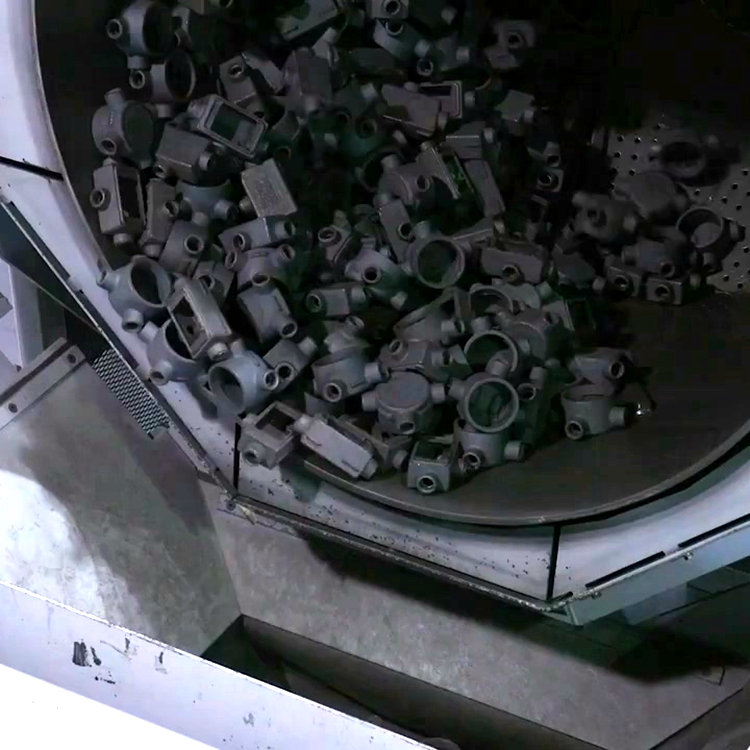

Барабанные дробеструйные машины используются в автомобилях,авиации и машиностроении

Модель QGT15-цена FOB 59 800 долларов США/комплект.

Продукты DETAILS

Барабанные дробеструйные машины используются в автомобилях,авиации и машиностроении

QGT15 Дробеметная установка с наклонным барабаном

Чтобы предоставить вам подходящую машину, пожалуйста, предложите нам сообщение ниже.

1》какую заготовку вы будете очищать?

Модели и

характеристики

QGT10

QGT15

Диаметр барабана*длина(mm)

φ1000×1300L

φ1500*1600L

Максимальная габаритная длина заготовки(mm)

450

600

Максимальная масса одной детали(kg)

30

40

Максимальный диаметр вращения(mm)

300

350

Мощность дробеструйной машины(kw)

22

30

мощность обработки(m³)

0.5m³

0.6m³

Максимальная грузоподъемность(kg)

800

1500

суммарная мощность(kw)

~48kw

~57kw

Пожалуйста, выберите модель дробеструйной машины, которая вам нужна, и мы предоставим вам ценовое предложение. Если вам нужно настроить специальные размеры, свяжитесь с нами, чтобы получить план и цену. С нетерпением жду общения с вами, это будет отличным началом.

2》Размер заготовок (длина, ширина и высота максимальной заготовки, длина, ширина и высота минимальной заготовки?)

3》сколько веса заготовки составляет максимум и минимум?

4》Производительность взрывных работ (сколько тонн или штук в день)

5》Пожалуйста, сообщите нам, что вам требуется эффективность очистки?

6》Лучше пришлите нам фото или чертеж заготовки.

1. Working principle:

The workpiece is placed in a rotating drum, which is driven by a motor to rotate continuously.

The high-speed rotating impeller generates centrifugal force, which throws the projectile material (usually metal pellets or abrasive particles) towards the workpiece surface.

The projectile material impacts the surface of the workpiece to remove the oxide layer, rust, grease and other undesirable substances to achieve surface cleaning.

2. Equipment composition:

Rotating drum: The main part is responsible for holding and rotating the workpiece.

Impeller system: Includes a high-speed rotating impeller that generates centrifugal force to guide the projectile material to the surface of the workpiece.

Projection system: Responsible for spraying metal pellets or abrasive particles for surface cleaning.

Motor Drive: The motor system that drives rotating drums and other moving parts.

Noise reduction device: used to reduce noise generated during operation and improve the working environment.

3. Applicable workpieces and industries:

Casting and forgings: including various iron castings and steel castings, cleaning scale and sand during the casting process.

Automobiles and auto parts: Used to clean engine blocks, crankshafts, brakes, suspension parts and other auto parts.

Machinery manufacturing: Surface cleaning of mechanical parts such as gears, bearings, springs, etc.

Aerospace parts: Clean aircraft parts and engine parts to remove oxide layers and coatings.

Steel structure manufacturing: Suitable for cleaning various steel structures and improving the surface quality of steel.

4. Equipment advantages:

Efficient cleaning: Through high-speed rotation and continuous projection, comprehensive and efficient surface cleaning is achieved.

Large projection angle: able to cover every corner of the workpiece surface to ensure cleaning without any dead ends.

Wear-resistant design: Key components are made of wear-resistant materials to increase equipment life.

Noise reduction design: Equipped with noise reduction device to reduce noise during operation and improve the working environment.

Good sealing: The equipment has good sealing performance to ensure the safety and controllability of the cleaning process.

5. Operation and maintenance:

Easy to operate: Equipped with automatic control system, easy to operate and improve production efficiency.

Regular cleaning: Clean the residue and abrasives inside the equipment to ensure the cleanliness of the equipment.

Lubrication maintenance: Regularly lubricate mechanical parts to ensure smooth operation of the equipment.

Check the electrical system: Check the electrical system regularly to make sure the electrical components are working properly.

6. Development trends:

Intelligent technology: Introduce intelligent control systems to improve equipment automation.

Application of new materials: Seeking more environmentally friendly and economical projectile materials to improve cleaning effect.

Energy saving: Introduce a more energy-saving motor system to reduce equipment operation energy consumption.

Customized needs: Adapt to more workpiece cleaning needs of special shapes and sizes.

Summarize:

Rotary drum shot blasting machines are widely used in many manufacturing fields through their features such as efficient cleaning, comprehensive projection, and wear-resistant design, providing reliable equipment for surface treatment of workpieces.